Les Deutsch's Theater Organ Project |

I have been using this page to document my project to convert a very large old analog theater organ to a modern controller console for Hauptwerk and other virtual instruments. The console is now completed as shown here. This page now serves as an historic record of the project.

|

|

|

I have been using the software product Hauptwerk together with samples from Neil Jensen's Keymedia Productions Connoisseur Theater Organ and my existing Rodgers 945 concert organ to play my theater organ music since early 2008. You can see how I do this on my Organ Design page. I probably would have been quite happy playing this way forever, using my touch screen display to control stops and my Rodgers combination pistons to make quick changes. However, when my friend Ken Rosen (who has a very nice two-manual Wurlitzer pipe organ in his studio and lives only three blocks from me) announced he was ready to give away a large three manual theater organ console, it was an offer to good to refuse. The console in question comes from an old analog Artisan organ from the 60s, probably their "Oriental" model. These were very large kits that were advertised in such places as "Popular Mechanics". This one would have cost approximately $7,000 in the 60s and was the top of their line. I have not been able to find any photograph or specifications for this organ in its original state. However, recent research has revealed that the console was once owned by Bob Leonard, an organ enthusiast who lives near China Lake, California. The photo below shows the console as customized by Bob, though it was not longer playable at the time the photo was taken in 2007. Bob, if you are reading this, thanks for making the console available!

|

|

You can look at the specifications I have designed for this organ.

The latest recording of the organ is my transcription of George Wright's recording of La Danza. Here is my arrangement of "Get Out, Get Under the Moon." It is inspired by the 60s recordings of George Wright. Here is the first recording made on the completed instrument, "Me and the Man in the Moon." It is my transcription of the Jesse Crawford recording. It shows off a lot of what the organ can do. Here is a recording of the tune "High Hat" made with the organ on June 25, 2011 to celebrate two years of progress |

|

Sunday, December 16, 2012 – The Console is complete!

| I was home for just a single day between trips to the East coast, I had been at meetings at NASA's Kennedy Space Center last week and I will be at Goddard Space Flight Center this coming week. Bruno had sent email to me while I was in Florida telling me that the console top was finished and I could get it on this one day. However, since rain was predicted, I asked Karen to pick up the top from Bruno on Saturday. Hence, when I arrived at home, the top was waiting for me. I took it to the lab and restored the wiring to for the music rack. Bruno had to remove this during his work. When Karen and I placed the top on the console, I had a bad surprise. The bolster was indeed sitting a bit too high and it was forcing the top to ride high at the front of the console so it no longer fit correctly. After about an hour of thinking, I came up with a solution that would avoid any modification to the bolster assembly. I decided to raise the top by 1/4". This is accomplished by inserting a 1/4" thick wooden piece under the console top hinge where it attaches at the rear of the console. I did not have a long enough piece of oak so I called Bruno. He cut a piece of poplar to the required 1/4" by 57 1/8" size. I had told him the depth was not critical as long as it was at least 3/4". I drove to his workshop and picked up the strip. When I got home, I discovered that the depth mattered after all! There was a small lip on the inside of the rear console piece that created a small recess for the hinge - and this meant the wooden strip had to be 1/2" or less in depth. I called Bruno again and he asked me to return and use his table saw to rip the piece to 1/2" After my second trip to Bruno's in a single day, I returned home with the correct size wooden strip. Karen and I placed it and the top on the console and I declared the console complete. |

|

| Now that I have a complete theater organ console - which plays beautifully - I took the mandatory console sweep photographs, Here you can see the pedal division. It is very complete for an organ of this size. The use of the "alternate traps" tab allows for a reasonable variety of traps. The piano stops on the organ use Key Rig rather than Hauptwerk for extra realism. |

|

| Here are the accompaniment stops, including the second touch stops on the straight rail (which is actually not straight on this console!) |

|

| Here are most of the Great stops - and the entire straight rail. In addition to the second touch stops, the straight rail has the usual compliment of replants as well as a set of "general" tabs to control things like the celestes and sostenuto functions. I relegated all non-traditional functions (including MIDI stops, combination system memories, and transposition) to the drawer so the organist sees only real pipe organ controls on the bolster. The Great is very complete - but some ranks and footages have been omitted because of the limitation on the number of stop tabs. I selected these carefully based on much research and discussions with other theater organists. All omitted ranks are available on the Solo, which couples to the Great. Hence the Great can still be used for a full organ ensemble. It is loud enough by itself anyway. |

|

| Here are the remainder of the Great stop tabs. Though I omitted a few ranks from the Great, I was not stingy on couplers. |

|

| The solo is also very complete. It has several color ranks that are available only in this division. I included the standard Wurlitzer couplers, but omitted the "Blackpool" couplers as unnecessary for the way I play. I also included many turned percussions.This photo also shows poff the two-tone wood finish on the console. My project is almost complete at this stage. Bruno will likely deliver the speaker cabinets next weekend. After that, I will start the final voicing of the instrument. I will also "wire" in a 12 rank Barton organ sample set that I have acquired. I might buy another large theater organ sample set before the end of the year, while such things are on sale. I'll decide next week. |

|

|

Monday, December 10, 2012 – The Classic synth module and some clever software

It was time in my test plan to configure the general midi (GM) synthesizer module that resides in my Classic controller. I had remembered to route an audio cable from the interior of the controller box when I put the back on the console. In order to use the same stereo channel for Hauptwerk, Key Rig (see below), and the GM Synth, I used "AU Lab", which comes as part of the Mac operating system. Au Lab allows you to connect many audio programs together and provides a mixer and effects (which I am not using, by the way). I configured AU Lab to accept the line input to eh Mac as one of the inputs to be mixed. I then wired the GM Synth's audio cable to the Mac's line input jack. I turned on the organ and enabled the GM stops - and I heard nothing! In case I did not understand Au Lab, I tried sending a known input to the line in and it worked perfectly. The GM synth was not working. I took the back (actually only one section of it) off the console and opened the controller box. I discovered there was no GM synthesizer there!

There used to be one - and I had played it before. Then I recalled that I had to replace the mother board in the controller box a while ago and I probably hadn't tried the GM synth since then. I must have shipped the synth back to classic with the old mother board! A quick email to Classic confirmed this and they shipped a new synth board to be the next day. It arrived last today and I plugged it into the mother board - and still I had no signal. However, when I looked through the block diagrams that Classic had shipped me with the controller, I discovered there was a jumper on the mother board that had to be repositioned to route the MIDI signal to the GM board. I moved the jumper and I had synth sounds again!

While the console was open, I fixed the only remaining problem I had found through my testing - two reversible pistons on the solo for which the piston light was not working. Both these problems were caused by my having placed connectors improperly on the side of the controller. I had used old photos of the controller to place them this way - and I must have changed their position to make them work! I too this photo of the controller to document the correct positions. |

|

| I have had to do a bit of software work on the Mac to make everything work properly. I wanted to continue using m-Audio's Key Rig to provide the piano rank for the organ. However, Key Rig seemed to stop functioning in Mac OS 10.8 and would not run on my Mini. After corresponding with m-Audio's support people, I was about to buy a new soft synth when I thought I would try a little more hacking. I had already determined that the only thing stopping Key Rig from working was a small application that the user has to run to tell Key Rig the location of its data folder. The application was written in PoiwerPC code which is no longer supported by the Apple runtime environment. I looked at the preference file for Key Rig (its a "plist" file, for you Mac people) and found that it contained a string with this folder location. I edited the file to have the string point to the data folder's location on my Mini. At this point, the latest Key Rig updater file from m-Audio ran after which I could run Key Rig again! I now had my piano rank again. I "wired" it so it keys from Hauptwerk and I also wired the sostenuto switch to act as a piano damper pedal. |

|

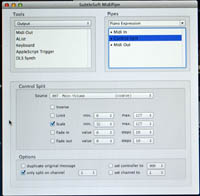

The last sep it getting the supporting software exactly the way I wanted it was to "enclose the piano." This meant wiring it to the percussion chamber expression pedal. This is not so simple. If you wire it according the HW instructions, by using the output defined in the continuous controller menu for that expression pedal, then you get a midi controller signal that goes from 0 to 127. Unfortunately, this means the piano sound goes completely silent when the chamber is closed - which is very unrealistic! Instead, I defined the expression pedal output on a new virtual midi channel and used MidiPipe (shareware for the Mac) to filter the midi data and send a new volume output to Key Rig. Here you can see the critical piece of this, a filter that rescales the 0-127 data to be 32-127 data. I settled on 32 by trial and error. With things set this way, the piano expresses about the same amount as the other tuned percussions.

All is now completed except the console top and speaker cabinets, which Bruno Legarce should deliver very soon. |

|

|

Wednesday, November 28, 2012 – Tidying up the Console and a new computer for Hauptwerk

| It is now time to put the finishing touches on the console. For the very first time, I secured the metal brackets that steady the bolster assembly. There secure with large metal plates to the inside rear of the console. They did not match up with any of the existing holes, however! I simply made new ones in the right places. The bolster is now very solid. |

|

| I had Bruno remove the wooden beam that sat under the accompaniment keyboard when he refinished the console. This was necessary to make room for the second touch contacts. However, this also left the bottom of the accompaniment (including the second touch assembly) open to the air. I was worried that some organist would, in a fit of rage or insanity, bring his or her knee up against the contacts and put them completely out of alignment. Hence I needed a new cover to sit under the accompaniment keyboard. K decided to attach it entirely to the key cheeks so that it could lift out of the console with the keyboard as a single assembly. Here are to lengths of nice lumber I used for the sides. The notches are required to clear the second touch assembly mounting angles. |

|

| Here is one of the side pieces attached to the underside of the key cheek. It is now painted black to add a stealth quality. The notch at the front will accommodate a metal angle on the cover assembly. |

|

| Here is the cover assembly on my workbench. It is fashioned from Masonite with a length of 1"x1" to provide stiffness. I screwed a length of aluminum angle to the front which will close off the gap under the keyboard. |

|

| Here is the cover in place on the organ and painted black. It completely seals off the underside of the accompaniment keyboard, providing excellent protection to the second touch contacts. I think this might be the last assembly I need to fabricate for the organ! |

|

| I purchased an Apple Mac Mini, 2.3 GHz i7 computer to run Hauptwerk (and other software) for the organ. It is dedicated tot he organ and will reside in one of the speaker enclosures when they return from Bruno's shop. Here you see the Mini sitting atop one of the speakers. I am using a small existing monitor to set things up. I also purchased a wireless keyboard and mouse so I can control things from the front of the console if needed. In addition, I installed software on the Mini and Karen's iPad so that I can control the Mini from the iPad. This will make voicing much easier when I get around to that. All that is left is getting the console top and speaker cabinets back from Bruno and everything will be completed. |

|

|

Friday, November 16, 2012 – Completely working - and with a back!

| After I returned from Washington DC on Tuesday, I spent spare time during the week "wiring" the stop controls to Hauptwerk. By Friday morning, the organ was completely playable - but without combination action. I was home early on Friday because of a doctor's appointment. I spent about an hour testing the SAMs using the Classic control system's internal diagnostics. Everything worked the first time except for a consecutive group of four SAMs in the Solo Division. My master wiring spreadsheet quickly indicated the errant cable - except I misread my spreadsheet and spent 30 minutes chasing down the wrong cable! After I discovered my error, I reseated the bad cable and all 165 SAMs were working. |

|

| This far, my Classic Organ Works controller (the "gray box") has been held closed by two little screws. This has allowed me easy access to the interior to set switches and check things out in general. I no longer need this easy access. My last act inside the "box" was to route an audio cable from its onboard General Midi Synthesizer to the outside world. You can see it in this photo as the black cable curving down at the left. Classic included buttons (which I placed in the drawer) to allow GM Midi sounds to be played from any of the five divisions - including the second touch. I then securely closed the box using a set of small screws that I had been saving for this moment. |

|

| In order to make assembly and removal of the console back easier, I routed call the cables that need to exit the organ to a cable tie that aligns with the "mouse hole" in the center back panel. There are four such cables: The main organ AC power, a switched AC connection to drive the powered monitor speakers, a USB cable that carries the console's MIDI messages to the Hauptwerk computer, and the aforementioned audio from Classic's GM synthesizer. |

|

| Her you can see the console with its newly fabricated back. Bruno Legarce fashioned the back in three sections, by my request. This makes each section fairly easy to move by one person. The center section has a small mouse hole at the base to allow the cables egress from the console. |

|

| Here is the organ, completely payable. It is now missing only a few items. Bruno will return the console top soon. I already have the music rack in the lab. Bruno will then return the two Rodgers speaker cabinets which will hide the powered monitors. I still need to buy a dedicated computer to run Hauptwerk. It is a bother to have to hook up my laptop each time I want to play. I am now on the lookout for year-end sales of the Mac Mini. In the meantime, I can now play the theater organ. |

|

|

Sunday, November 11, 2012 – Coming back together, and playing again

| After a quick trip to Cleveland this week, I returned on Friday and began reassembling the console. Bruno has returned most of the parts so there was a lot to do. I started by reinstalling the accompaniment (bottom) keyboard. I hooked up all the cables and adjusted the primary contacts. I then adjusted the second touch contacts. Surprisingly, it pretty much worked the first time! This is the first time I have ever owned an organ with second touch. IT will take a while before the technique becomes "second" nature. I then continued the assembly process by putting the great (middle) keyboard in place. It did not quite line up with the holes I had made in the console. This worried me until I installed the solo (top) keyboard. The solo lined up with the existing holes. I made a series of measurements and compared things with my Rodgers again. I got the middle keyboard din position and created ne holes to fix it from the sides. I also adjusted the metal triangles that hold it on the back. The keyboards were in place and all working. I also tested the piston wiring. I located several small cable errors - either an 8-pin connector inserted one pin off or a common wire that was not reattached to the controller. By sunday afternoon, the keyboards and pedalboard were all playing properly. |

|

| After dinner on SUnday, Karen helped me reattach the bolster assembly. If I am very lucky, this is the last time we will have to move it. The overall look of the console is excellent. Bruno has done a fantastic job in refinishing the woodwork. He also created small ebony wedges that fit under the two upper keyboards and virtually close the gaps that were visible from the front. I had no time Sunday to actually begin testing the bolster and its 165 SAMs. I had to fly away to Washington DC early Monday. The organ will have to wait until next weekend for more progress. |

|

|

|

|

Friday, September 28, 2012 – A new switch and a new web page

|

Saturday, September 15, 2012 – Time out for Hollywood

| Over the last couple of days I have reinstalled the power supply, midi interface, and Classic controller in the console. I have also taken the opportunity to straighten out some of the internal wiring. Work had to stop today, however, for a strange reason: our house was being used to shoot an episode of Cartoon Network's Adult Swim series "NTSF:SD:SUV::". If you haven't heard of this show, it may be because it airs late at night. It is the creation of comedian Paul Scheer, who also stars as the leader of a band an antiterrorism squad in San DIego that uses a fleet of SPorts Utility Vehicles. This photo shows a typical yellow film production sign. These are very common in our neighborhood - but they usually do not point directly to our front door. |

|

| Here is Karen posing for an iPhone shot with the cast of the show. Rebecca Romijn is on the left. Next to her is June Diane Raphael. Karen is next. Brandon Johnson is to the right of Karen. Paul Scheer is on the far Right. Kate Mulgrew, who played Captain Janeway in Star Trek Voyager, is also a regular cast member, but she does not appear in this episode, aside for some voice-over work. THis was too bad because Karen is a huge Star Trek fan. |

|

| During most of the shoot, the theater organ sat in the kitchen - except for during the one scene that was filmed in the kitchen of course. The crew was very careful with the organ, and all the rest of our possessions. |

|

| At the end of the day, which was close to midnight, everything was put back the way it started in the morning. Here is the organ, once more in the family room, waiting for me to continue work tomorrow. |

|

|

|

Saturday, July 21, 2012 – A visit to the console

| This is not a photograph of my completed console. I have been up to a lot since I last wrote in this blog. I spent two weeks in Toulouse, France speaking at two technical conferences for my day job. I did get a chance to hear an organ concert of French Romantic music on the famous Cavaille-Coll instrument at St. Sernin's while I was there. I then returned to Los Angeles and immediately took a week off to attend the national convention of the American Theater Organ Society (ATOS) which was being held in Los Angeles. This is the first ATOS convention I had attended in more than a decade. It was strange to spend most of six days hearing never-ending organ concerts. The convention made me want to play my own theater organ - but alas it is not yet complete. The photo is of the 77 rank Wurlitzer organ at the Nethercutt Collection in Sylmar, very close to my home. These people have a lot more SAMs to contend with. |

|

| The following week I played a concert with the Night Blooming Jazzmen at the First Presbyterian Church of Granada Hills. As usual, I tried out the pipe organ. I recognized it from the portfolio that Bruno Legarce had shown me. It is an organ case and console that he built when he was working with Manual Rosales. I played the organ for a while - long enough that the pastor asked if I would be interested in working there! The wood work on the organ is magnificent. I know Bruno was the right person to refinish my console. |

|

| Today I went to Bruno Legarce's shop, behind his house, to see the progress on the theater organ console. There are pieces of various organs all around the room, as you can see in the photograph. My console is in the center. It is the same shape as when I saw it last, but the wood looks entirely different. Bruno has completed the removal of the old finish and repairing of some of the veneer. The console looks great. You can now tell that Artisan used very nice wood for their consoles. |

|

| Here is a closer shot of the console, showing the quality of the wood. I brought the accompaniment manual (complete with second touch) with me to leave with Bruno. We spent a little time seeing how we might modify the crossbeam that runs under this manual to make room for the second touch contacts that now hang below the keyboard. Bruno will do this, fill in some of the wood grain on the console, and finish it, the pedalboard, the bench, the key cheeks, and the speaker cabinets to a dark wood shade. He showed me the various possible stains and I selected a dark one that was close to the darker of the two speaker cabinets. Bruno intends to have the console completed before the end of August - which means I will then begin reassembling the parts and playing the organ again. |

|

|

Friday, March 31, 2012 – Closing the gap

|

Monday, March 26, 2012 – Final fitting the 2nd touch contacts

| Now that I knew the Peterson keyboard contacts would work, I needed to do final adjustment and mounting. Some of the 2nd touch springs simply did not come to rest on the rail I installed. This meant the corresponding keys had to have additional throw to engage the second touch. In order for this to feel right, I had to pace additional felt washers on the keys' screws. This was not a satisfying fix. Instead I ordered thicker aluminum and created a deeper rail. You can see this in the photo. This solved the problem with the springs, but now the springs would click against the bottom piece of wood that holds the piston rail in place. I therefore had to cut a piece of this board away. I used a coping saw so the line is far from straight - but it never gets seen anyway! With the deeper rail, I also had to mount the Peterson contacts a bit further from the springs. I did this by using only two nuts rather than three for spacers. I had to hacksaw four screws to the new proper length to accomplish this. |

|

| Here is a view of the bottom of the 2nd touch mechanism. You can see how poorly my cutout is in the board! However, it was quite necessary. |

|

| All the keys now have a reasonable 2nd touch feel. I readjusted all the primary and 2nd touch contact points and everything seems to work correctly. With the keys now having an extra ~1/4" of throw, there is a gap of that same size between the key bottoms and the piston rail. In order to close this gap, At first I thought I would fabricate a new piston rail that is 1/4" taller. On further inspection, I admit this will not work! The keys would simply hit the top of the new piston rail at about the same depth that they would engage the2nd touch springs – completely negating all my hard work. I think I have to live with the gap. The only alternative I can see is to extend the white plastic key fronts down by 1/4", which would be a great deal of work! |

|

| Bruno came by and picked up most of the rest of the organ. He has finished the major sanding of the console shell. Now he also has the bench, pedalboard, and the two old Rodgers speaker cabinets. Here is the empty space in my family room! |

|

|

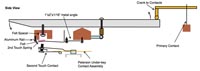

Wednesday, March 7, 2012 – Test fitting the 2nd touch contacts

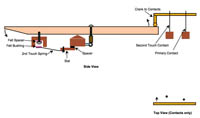

Here is the latest design I have for second touch. The primary contact is simply the existing crank contact on the back of the keyboard. The second touch springs are mounted to the aluminum angle that is in turn secured to the keyboard pivot block. In order to pretension the springs, I have secured an aluminum rail to the forward ridge of the keyboard stop block as shown. I have increased the thickness of the felt spacer that sits on the screw that in turn defines the key throw. I have placed felt on the upper side on the 2nd touch springs so they do not click when struck by the key screws nor when the springs snap back to the rail.

This design assumes use of the Peterson underkey contact assembly, shown at the bottom of the diagram. This assembly is mounted so the 2nd touch springs engage the Peterson contacts. Hence, there is no way to accidentally "fire" a 2nd touch contact. The springs must move before a 2nd touch note can play. |

|

I corresponded with Scott Peterson. Scott has provided much help to me during this project. He graciously offered to send me a set of under-key contacts that I can return within 30 days if I cannot make them work in this configuration. This complicated my testing slightly because I had to come up with novel ways of mounting the contacts that did not damage them in any way! It took two evenings of thinking - with Karen's assistance - before I settled on a method that would hold the contact assembly securely in the right position (or at least close enough for testing) and not modify the Peterson parts in any way. First I had to verify that I could affix some metal brackets to the bottoms of the key cheeks. Since the console is out for refinishing, I had to search my extensive photo library to verify I could do this and still fit the keyboard into the console.

I mounted small metal angles on the two key cheeks. These in turn attach to the two metal angles that came with the Peterson assembly. I turned the Peterson angles upside down and also used a stack of nuts as spacers so that the Peterson metal channel is suspended approximately the right distance below (above in the photo since the keyboard is upside down) the 2nd touch springs.

The small circuit board visible on the right is the Peterson pedal contact circuit card - see below. |

|

| Here you can see, in end view, how the parts fit together. Compare this to the drawing above. When a key is depressed, it goes through most of its throw before tits screw engages the 2nd touch spring. At this point, the key starts bending the spring, resulting in increased resistance. Slightly later, the Peterson contact engages, turing on the 2nd touch sounds. Notice how all of this adds only about an inch of depth to the keyboard. There should be no conflict with the organist's knees. |

|

In addition to finding a non-destructive way to mount the contacts, I also had to find a non-destructive way to test them. The Peterson contacts come with a cable that, unfortunately for me, is not compatible with the MasCon connectors I use. Hence I could not simply connect these to my test keyboard. Instead, I went back to the pedalboard and disconnected its Peterson circuit card. This card has two purposes. It serves as a junction for a removable cable linking the pedalboard to the console. It also contains an array of LEDs that are used to test the pedal contacts. There is no reason the same LEDs can't be used to test the keyboard contacts, since they take the same connectors! I can only test a couple octaves of the key contacts at a time - but that is a minor inconvenience. Here you can see me depressing two keys into their 2nd touch region. You can also see the two corresponding LEDs lighting on the circuit board.

I will do a bit more testing before deciding to buy the contacts (I place that probability at 90% today). Then I will need to mount them a bit better and come up with a cover to protect them from knees. |

|

|

|

Monday, February 25, 2012 – Second Touch Saga – Part One: Springs

| There is only one big problem left to solve for this project: adding second touch to the accompaniment manual. This one has bothered me for a long time and I have kept pushing it off until later. Now there is no more "later"! Luckily, I had an experience that energized me to work in earnest on the second touch. The Night Blooming Jazzmen was invited to perform at the Fresno Mardi Gras Dixieland Festival in February. Before I left, I made contact with the family that runs the Warnors Center for the Performing Arts in downtown Fresno. They have a completely original 4-14 Robert Morton theater organ that is restored and used as part of the theater's operations. The owners and staff welcomed me and made me feel like a VIP during my short visit. The Robert Morton also has the best adjusted second touch that I have played to date. It inspired me to work harder on my own. Karen took this photo of me playing the organ at the Warnors - though I am way underdressed in my NBJ uniform of the day! |

|

| Although I had experimented a bit using very powerful, yet small, magnets to implement the second touch springs, I soon reverted back to my original concept of using the Wurlitzer replica springs I purchased from OSI, mounting them so they engage the screws that define the throw of the keys. You can see the concept in this photograph. I attached the springs to a length of aluminum angle. This should give enough strength to resist bowing since I attached the angle to the keyboard only at the two ends. I added a piece of aluminum bar stock - visible under the ends of the springs. This forces all the springs to be pre-stressed and provides real definition of the beginning of the second touch throw. Without this piece, many of the spring ends were suspended in midair. |

|

| Here is a photograph of my first attempt at mounting the springs in this way. The problem with this turned out to be the word "should" in the previous paragraph. I had not calculated the effect of 56 springs pushing in unison. The aluminum angle stock ended up having a non-trivial bow away from the keyboard. This resulted in achieving second touch only in the top and bottom octaves! The concept was sound - but the implementation was inadequate. |

|

I purchased bigger angle stock. The next largest size required the angle to reach one full inch toward the keys. Karen and I carefully measured this and decided it would work. Here you see the new angle stock, drilled and ready for the springs. The old assembly is shown next to it for comparison. The large angle had two advantages. First, the larger, 1" depth provided increased resistance to bowing. Second, the increased depth (2") allowed me to secure the assembly to the wooden piece that holds the key pivots. This creased a much stronger mounting. |

|

| Here is the nearly finished spring assembly installed. I still need to add the last few springs on each end. They need to be attached a bit differently. It is possible I will completely leave out to high and low "C" because there is no reasonable place to mount their springs. I don't think this will create and real performance limitations. |

|

Here is the finished result. I am pressing two keys to the bottom of the primary throw and the middle key to the bottom of the second touch throw. The keyboard is fairly well adjusted. I ended up having to use two thicknesses of felt washers, with deeper ones toward the center of the keyboard.

The next step will be adding the remaining springs and then the contacts. I am now devoting my though toward how I will mount the contacts. |

|

|

Monday, January 16, 2012 – Some minor keyboard repairs

| Now that my family room is once again organ-less, I turned my attention to the three keyboards now being stored in my lab. The upper (solo) manual has suffered from clicks in the top octave. As shown in the photo, the previous owner was a bit too gung-ho in carving wood away from the keybed to make room for pistons. In the bottom half of the top octave, there was not enough wood left to support the felt that cushions the keys at the bottom of their travel. This meant that the keys only stopped when their own wood hit the wood bottom of the keybed, resulting in the aforementioned clicks. |

|

| I solved this problem by cutting a piece of 1/8" pressboard to fit in the "too-deep" depression of the keybed. I fastened it in place with a coupe of small wood screws, taking care that the piston rail assembly would still fit. The pressboard gives the felt just enough support - even though I did not glue the felt to the pressboard The keys now have the expected cussioned bottoming-out. |

|

| The second keyboard problem I addressed today was probably also caused by a previous owner's gung-ho drilling to make room for pistons. For some reason the lower couple of keys on the accompaniment manual must not have been safely out of the way. As a result, there were gauges cut into the low C and C# keys as seen in the photograph, which was taken a while ago. Bruno mentioned this when he helped me disassemble the console. He went to his truck and returned with a small piece of plastic about four inches long that was formed into the shape of the bottom of an organ key. It was a real good match for this keyboard too. |

|

| I carefully removed just the vertical part of the key facing on the two errant keys. I did this by taking a sharp model knife and scoring a line about half way through the plastic just below the bend. I then carefully wedged the blade of my knife between the plastic and wood of at the bottom of the key. I pried the plastic back, away from the key. As expected, it broke cleanly at my scored line .I then used a couple of needle files to carve away the plastic facing all the way to the bend. I cut pieces out of the plastic key stock Bruno had given me and filed them to fit. I then used some glue to secure the replacement facing pieces. Be sure to use glue that adheres to both plastic and wood! |

|

| The results are excellent. You would have to look very closely to see that new facing is a slightly different color and thickness than the original. |

|

|

Saturday, January 14, 2012 – Sending the console for refinishing

| With only the refinishing, second touch, and installation of a dedicated computer left in the project, I chose to proceed with the one item that is the least work for me: refinishing. I had intended to offer the task to the kind cabinet maker who ripped the piston board molding to size for me near the very beginning of the project. In fact, I tracked him down and sent him some photographs of the console. He rejected the project as being much too delicate and artistic a job for his kitchen cabinet business. I then began asking my local organ industry friends if they had a person they could recommend for this task. The same name kept coming up: Bruno Legarce. I called Bruno and he seemed interested. He came to visit and I showed him the console. It did not scare him off. Bruno brought along a portfolio of organ consoles and pipe organ cases he has built. It was extremely impressive. It turns out that I have played a few of the organs that Bruno has built – so I know he can do a great job. Here is a photo of a recent console that Bruno has built for a customer who is also using Hauptwerk. It makes mine look very sad! Bruno agreed to take on the task when some time freed up in his schedule. That freed up time has now arrived. |

|

| Bruno came by this morning and he helped me disassemble the console. I thought it was important for him to see how the parts fit together since there are certainly some non-standard solutions here! It was sad to take the organ, which was completely playing (minus the second touch) and tear it down nearly to the state in which I acquired it. Here is a view of the family room with the almost-empty console shell. We removed all the active electronics, including the Classic controller box. |

|

| We moved most of the innards of the console back to my lab. Here is a photo showing them stacked up. You can see the bolster assembly, the three keyboards, and the drawer. The power supply and MIDI interface are just out of view here. The pedalboard is behind two of the keyboards. Bruno will start with the console shell and top, and come back later for the pedalboard and bench. |

|

| Here, in a scene reminiscent of the arrival of the console shell, is the same shell leaving my home once more. You can see Bruno securing the shell to his trailer. I know the next time I see it, the console shell will look quite a lot better. |

|

|

Saturday, November 19, 2011 – Speaker cabinets reclaimed

Karen and I are now working to secure someone to do the console refinishing and minor woodwork. I will report more on this in later posts. In the meantime, I decided to work a little on the speaker cabinets. I have two 1960s Rodgers speaker cabinets left over from my old Rodgers 32B organ. We sold two with the organ and kept two. One of these has been used in my house for the last 15 years as a display table in my living room. The other has served a similar purpose at my parents' house. I went to visit ,my Mother on Friday to celebrate my daughter passing the California Bar. After we returned from dinner. I emptied her speaker cabinet of its amplifiers and speaker cones. The later were affixed to a rear panel. I loaded these separately into my station wagon - so as not to have to carry a single unit that we too heavy. It was already heavy enough for Karen and I without the speakers and amplifier.

This morning, before Karen awoke, I did the same to our Rodgers cabinet. I carried it into the Family room. Karen was right about the finishes being quite different. I am not sure if they were always that way or if ours faded more because it was in a more sunlit room.

After Karen woke, she helped me rearrange the family room as you can see in this photo. Our fireplace is once again useable. |

|

Here you can clearly see that the right hand speaker cabinet is darker. I will have the console and lighter speaker cabinet refinished to match the darker one.

The console is still sitting on carpet because it still needs glides added to sit directly on the wooden floor. The console and speakers will sit closer together after refinishing. The console will also sit about 8" closer to the wall.

Since the back panels of both cabinets are removed, I simply placed the JPL powered monitor speakers inside, facing the wall. The right hand cabinet contains the subwoofer in addition to right monitor. Although there is plenty of room inside for the computer as well, I am placing it atop the cabinet for now so I can get to it more easily. When I have a dedicated computer, it will live inside. |

|

|

Friday, October 21, 2011 – Thank you, thank you, SAM I am!

| Last week Karen and I took the bolster out of the organ, placed it in its cradle, and moved it back to my lab. I removed all the errant SAMs. For good measure, I also removed the remaining four tong transplant SAMs as well. Here you can see a gap where I have removed a pair of SAMs. I unsoldered the three wired from each and then carefully unscrewed and removed each SAM. I moved the stop tabs to SAMs from my old purchase of still-in-their-original-box SAMs. I then mounted these. In some cases I needed to drill new pilot holes for the mounting screws since the newer SAMs have holes rather than slots for the screws. |

|

I had to use a hack saw to cut away metal from the bottoms of three of the new SAMs in order to make them fit. This was not as scary to do now that I know that this didn't hurt the SAMs the first time I did this. Still, it was a bit unsettling to mutilate these essentially brand new SAMs. With nine SAMs replaced, we moved the bolster back to the console. All but one SAM worked! The Solo octave coupler SAM would cancel but not turn on with its magnet. I verified that the magnets both worked and that the wiring was all correct. It had to be a mechanical problem. I noticed that if I held the tab 1/8 of the way down and pressed a piston, it would turn on the rest of the way. I decided that the stop tab angle must have been adjusted too far out of spec - which surprised me since I assumed the SAM would work for any amount of angular adjustment that was physically possible. This was not so - and I consider this a design flaw in the SAM. Karen helped me lift the bolster to a table in front of the console this afternoon. I remounted the last errant SAM about 1/16" higher on the bolster. We placed the bolster back in the console and now ALL THE SAMS WORK. All 165 SAMs are now working.

Now there are only three tasks remaining on the organ console project:

1) Refinish the console,

2) Install second touch on the accompaniment manual, and

3) Procure a dedicated computer for the console.

Task 3 is trivial and should be left until last so as to get the most computer for the same money. I will likely proceed with task 1), refinishing the console. However, first I intend to play the organ for a while! |

|

|

Sunday, October 9, 2011 – New audio system - It sounds great!

| This photo is a bit of a cheat. It was actually taken on September 24, 2011 - before the previous post. It shows Ken Rosen, my friend who gave me the free console that began this project, trying the organ out for himself. |

|

| I spent most of the first week of October in Washington DC. Karen and my wedding anniversary was on October 5 and we were 2,500 miles apart. However, she got me a present anyway. When I returned on the evening of the 6th, I found that Karen had picked up the JBL sound system we had ordered for the organ. It arrived at Sam Ash while I was gone. We unpacked the speakers before I went to sleep. I took the 7th off to prepare for Rosh Hashana services, so I hooked up the speakers before Karen woke. I then turned everything on and played "Oh What a Beautiful Morning" at near full organ. It was a larger and fuller sound than with the temporary vintage HiFi system I had been using up to this point. Karen, however, slept right through all of this! This photo shows the organ with the new JBL system installed. You can see the two powered 8" studio monitors on the cabinets to either side of the console. |

|

| The JBL system also contains a powered subwoofer. It is shown in this photo taken behind the console. WIth this system, I finally have a well-balanced pedal division and I can actually hear the big 32' diaphone. In fact, several notes in the lower octaves caused rattling in various objects in the room. I tracked most of them down and mediated the problems. However, two notes still rattle the flue in the fireplace! Since the organ will eventually move to the opposite end of the 30' room, I won't worry about these for now at least. Karen and I are going to the Sun Valley Jamboree - a big jazz festival in Idaho - net week, so I will put of reworking the errant SAMs until after I return. In the meantime, I have gotten a lot of time to actually play the organ. |

|

|

Sunday, October 2, 2011 – Work in progress: Speakers and SAMs

Now that the organ actually plays, it is harder for me to take it apart to do any new work! Karen and I spent some time over the last few days shopping for the audio system. We visited several local music stores and finally placed an order for a pair of JBL LSR2328P powered studio monitors and a matching LSR2310SP powered sub woofer. These will be available to pick up in a couple weeks. I also built up the courage to remove the console top and continue fixing wiring problems with the SAMs. I used four memory levels on the capture system to map each stop tab to a piston so could make repeated SAM tests in arbitrary order. I determined that there were still 11 SAMs that were not working properly. However, four of these looked like easy wiring repair projects. Two pedal SAMs were "wired together" so that a piston set for one would turn both on. The cause was a short between the signal wires on the two SAMs - located on the left circuit board I had built for the bolster interconnections. I used a small file to clear the soldered short and the tabs were once again independent. A second pair of tabs in the Great were linked so that canceling the first one caused the second to turn on. This was due to a similar short - but this time in the magnet wires between the adjacent SAMs. Once more, a few strokes of the file solved the problem.

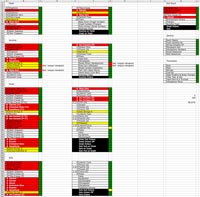

The SAM scorecard shown here lists the current status of all the SAMs on the console. Every SAM is "green" except for seven. Of these, only four are really "dead". The remaining three are "sticky". I have more than enough spare SAMs to replace all of these - so that is an upcoming project. |

|

|

Monday, September 19, 2011 – Its really an organ now!

Last Wednesday, after an evening spent at my mother's house setting up her new high speed Internet, I returned home to find the new controller board from Classic on ,my doorstep. I carefully swapped out the board and began testing the organ once again. It took a couple evenings to connect everything up once again, carefully checking the functionality after each step. It was all working - modulo the few errant SAMs that I already had identified. By Saturday, I had a fully functional organ for the first time. Every stop and every control works. I programmed everything to Hauptwerk and even spent a little extra time rerouting the MIDI for the piano rank to an external software synthesizer. I now have the following items left to complete the project:

• Replace or repair the remaining errant SAMs

• Add the accompaniment second touch

• Refinish the console

• Procure a dedicated computer for running Hauptwerk

• Add a better audio system

I decided to progress first to the audio system. I invited Cory Edelman, an old friend who is also a theater organist and an audiophile, to visit. He played the organ for a while, as shown in the photo, and gave me some advise on audio components.

|

|

It is time for a new video clip of the organ in action. Still photos cannot convey the fact that the stops actually move and the notes actually play. Hence, I mounted my Nikon 3100 camera on a tripod and played a short piece, "Indiana Lullaby." The idea is to show off the functions of the organ .Click on this photo to run the video. It is in MOV format.

In the video clip you can clearly see the combination action working. I even use the sostenuto effect at the end. I am off to Washington yet again tomorrow so I will not be able to work on this again until next week. |

|

|

Monday, August 29, 2011 – A break in the project to remember my father

On Wednesday, August 24, my father, Ralph Deutsch, passed away at the age of 91. He is the one responsible for my interest in the organ and the one who made sure that I had top notch organ teachers from the very beginning despite the fact that I had not previously studied piano. In addition to all the things he meant to me, my mother, and my sister, he was a successful mathematician, physicist, and inventor. He authored six technical books and held 147 U.S. Patents - so many that he became a patent agent in order to file them himself. He was the inventor of the first digital organ system that became the basis for the Allen Computer Organ that revolutionized the electronic organ industry in the late 1960s.

In order to make room in our home for the throngs of mourners who visited for food and religious services after the funeral last Friday, my daughter and I moved the theater organ to yet another new position.

I will be creating a web page to honor my father in the near future. In the meantime, we have suspended work on the theater organ until at least next week.

Update - Friday, September 9: I have posted most of the web tribute to my father. Click here or follow the new link in the banner on this site. |

|

|

Monday, August 23, 2011 – A drawer to hold the controls

| I began experiencing a strange problem with the console controller system. After working flawlessly since it arrived, it suddenly began generating internal reset signals. At first, this happened every few minutes, but the frequency has increased to the point where a repair is necessary. Classic has been working with me on this and will be sending me some new parts momentarily. In the meantime, I decided to catch up on a few tasks that I had been putting of. The first of these was constructing a drawer to hold the display and button arrays that are used to send commands to the controller. These are, of course, not traditional theater organ controls, so I did not want them to be mounted in prominent positions on the console. This was just as well since I left no space on the bolster anyway! I had long ago decided to build a drawer that would mount under the console to one side. The controls would only be visible when the drawer is pulled outward. I used some oak-finished 3/4" plywood left over from a shelving project that Karen had done. I used actual size printouts of the required holes as guides. Notice these are rectangular holes. My inventory of power tools is limited, so I simply drilled 1/4" holes near the corners of each cut and used a hand coping saw to make the holes. Due to obvious geometric constraints, you have to remove the saw blade and reinstall it inside the drill holes. Actually, these cuts were still pretty easy to make. |

|

| You probably noticed how non-rectangular my holes actually are! This is why I highly recommend buying the optional metal bezels that are made for the control boards. Here, in this view that shows a test fitting of the components to the plywood board, you can see how these bezels cover up all my mistakes very nicely! Notice I have relocated the on/off key switch to this board too. I had originally intended to place this drawer on the right side of the console. Unfortunately, the cables that shipped with the control boards were not long enough for this. I decided that rather than building extension cables, I would mount the drawer on the left of the console. This necessitated moving the keyswitch - which would otherwise have been blocked by the drawer! The additional dial above the keyswitch is a knob for adjusting the reiteration rate of the tuned percussion stops. |

|

| A drawer must be built "square" (rectangular, actually). Otherwise, it will bind or simply not move at all. Hence I purchased joiner's right angle clamp. This holds pieces at a precise right angle allowing you to glue and nail the pieces correctly. This is very important so don't skimp on this step. |

|

| Here you see the major pieces of the drawer completed. It is shown upside down on the workbench. The plywood panel is on the bottom. It is secured with screws to gusset blocks mounted on the sides of the drawer. Additional blocks are used to mount the removable bottom plate which I fabricated from some leftover masonite. I made the front of the draw wider than the sides to hide the drawer hanging hardware a bit. |

|

| Here is Karen testing the drawer. I have mounted it upside down to a spare piece of plywood in the "lab." Notice I am actually reusing the jig we constructed for winding spools of wire! In fact, Karen also used this same board to test the stain formula before staining the drawer (see below.) The drawer hangers are designed for mounting computer keyboard drawers under desks - a perfect analog for this organ application. Most drawer hardware mounts to the sides of cabinets and would be much more difficult to use in this situation. |

|

| Here is the drawer installed under the left side of the console. All the components are mounted so they can be easily removed for servicing. Notice that I even added some MASCON connectors to the keyswitch and reit rate potentiometer. I tied all the cables into a single bundle using a generous supply of cable ties. These are anchored to the back of the drawer using some old plastic cable clamps. The cable then hangs in a small loop in the two-inch space behind the drawer and in front of the console fall board. This provides the slick needed to open and close the drawer. Don't forget this step or the drawer will only last for one use! The other end of the cable is routed through the console to the Classic controller box. |

|

| Here is the completed drawer. I used some half-round molding to dress up the seam between the plywood panel and the drawer sides. This was necessary because the panel was actually a bit off square. I think it looks better this way anyway. It has the added advantage that when sitting upside down on the workbench, the molding keeps the buttons from contacting the surface. Here you can also see that Karen did a great job matching the console color. Of course, I intend to have the console refinished later - but by this time I may also have the updated controller with the wireless controls. |

|

| Here is the completed drawer in the context of the entire console. It looks pretty good. It has to hang a couple inches lower than I would have liked in order to clear a major structural wooden beam that holds the console together under the keyboards. Other than this, it looks quite professional. |

|

|

Wednesday, August 3, 2011 – SAMS are all wired - and nearly all working

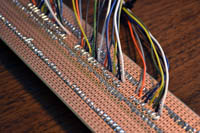

| Based on the success of the first third of the bolster wiring, I continued with the other 2/3. Here you see one of the cable assemblies that connect the bolster to the console controller. The ~100 wires are tied into two cables. Each wire is soldered to the small circuit board that also contains two rows of headers to receive the connectors from the bolster. I clamped the two plastic wire spools to the table to allow me to assemble the cables on my six foot table, even though the cables range up to 12 feet long. |

|

| Here you see two of the six bolster cable assemblies installed. Two of these go to the left of the bolster, two to the right, and these two in the center back of the console. The cables leaving these boards are routed to the console controller. |

|

| With the cable assemblies in place, all that was left was to complete the wiring to the SAMs. Here is the bolster assembly sitting on its cradle and fully wired.This was a very big job. After wiring, I used the cheap Yamaha synthesizer to test the Reisner SAM switches, which I had carefully bent into reasonable positions. I "played" the stop tabs and isolated ciphers (switches stuck in the "on" position") and tabs that did not make good contact. The last step was to retest all the magnet coils to make sure they all still had the required 28 ohm impedance. |

|

| Here is a close-up of the SAM wiring. Sometime during the wiring, I realized I had a problem with the method I was planning to use to isolate the SAMs into groups of less than 28 to attach to the 12 VDC drivers in the controller. I had created groups of this size that had their commons wired together - but then I saw that consecutive rows of SAMs sometimes were so close that they touched. Since the commons are wired to the chassis of the SAMs, this defeated the isolation! I rethought the groupings and made changes. You can see some of this here. Look carefully and you will see places where I have cut the bare wire that connects the SAMs in horizontal rows. In addition, you will see occasional red wires (I used red for 12 V lines) running between the rows. By the way, this photo would make a great jigsaw puzzle! |

|

| Karen and I carefully moved the bolster assembly back into the console - without bending any SAMs switches! Here you see the left bolster cables plugged into the connector boards. |

|

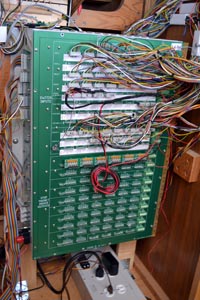

| The controller is getting full. At this point, all the wiring is complete to the connector with the exception of the accompaniment second touch contacts - which I have not yet built. These will go to the row of empty headers near the top of the controller. The bottom three rows of the controller contain no electronics - which means Classic uses this controller type for organs with even more SAMs than mine! The cables that exit the controller vertically in this photo are the ones connecting the Classic display. I will reroute these in a more logical place later. |

|

| This is a good overall photo of the organ as it stands today. The cover is removed so I can continue to track down problems with the SAM wiring. I am pleased to report that, as of now, 158 of the 165 SAMs are working properly. Most of the errant ones are tongue transplant patients - so I will have to either work on them a bit more or simply replace them with spares. I have more than enough spares to get the rest working if need be. Notice how I have mounted the Classic controller display to a handy piece of 1x1 lumber so I can reach it while sitting at the console. This is also a good view of the connections between the bolster and the console. I can remove all the bolster cables in less than a minute when the bolster needs to be serviced. I have also wired all the stop tabs to Hauptwerk so that the organ actually plays like an organ - without the need for a computer touch-screen and without undue reliance on the pistons. |

|

|

|

Tuesday, June 28, 2011 – Its been exactly two years - and a lot of progress in the last couple months!

It has now been two years since the day we moved this theater organ console into our home. Today (or actually two days ago) we had a playable organ. I decided to record a tune on the organ before dismantling it to work on the bolster wiring. Here is "High Hat", a novelty tune by Louis Alter. He is much better known for composing "Do You Know What it Means to Miss New Orleans?" However, "HIgh Hat" is pretty well-known in theater organ circles because the great organist Jesse Crawford made a recording of it when it was new. It is a difficult piece and demonstrates that I have successfully adjusted the keyboards!

When I decided to start this project, I gave myself a budget and schedule. So far, I am still under budget - but now that I have bought most of the controller, I am getting a lot closer to my cap! My schedule was to complete the project within two years. Clearly I am running late. Of course, much of the delay was caused by the controller not being ready when expected - resulting in a very slow year last year on the project. I am certainly happy with the progress since the controller was delivered - so I will press on.

Now, back to the bolster wiring. I calculated the amount of 26 gauge wire I needed to complete the console - about 6,000 feet. Since I didn't want to waste money buying wire in measly 100-foot rolls, I bout eight 1,000 rolls, 1,000 feet in each of the eight colors I use in my cables. However, I still wanted to use the dispenser I built for smaller rolls. Hence I needed a way to get wire off the 1,000-foot spools and onto something more manageable. Karen and I built a jig to do this. This photo shows a crank assembly into which we can clamp an empty small spool. We used a threaded rod and a crank made for window casings. The trick was using these two tapered washer/nuts. They clamp against the spools and hold them tight and centered on the rod. |

|

| Here is Karen loading wire onto a small spool. The large spool is on a second threaded rod and is free to spin. As you crank the small spool, you have to feed the wire horizontally on the little spool. I calculate that we get about 200 feet of wire onto these small spools. The small spools, by the way, are left over from the wire I have already used on the project. The entire spool winding jig cost about $20 in parts, including lots of leftover screws, washers, and nuts that I can use elsewhere. |

|

| Although I could certainly wire the 165 SAMs on the bolster directly to connectors on the Classic controller, this would be silly. In order to disconnect the bolster later I would have to remove dozens of connectors and reroute all the cables. Instead, I decided to build connector boards close to the bolster. Three of these, located to the left, right, and in back of the bolster, will allow short, removable cable connections. The bolster will still be hard to remove (because it is heavy!) but at least the wiring won't get in the way. I purchased several circuit boards from my local electronics store. These have the same "pin-outs" as standard prototyping boards. I soldered headers (pins that connect to the MASCON connectors and mount on circuit boards) to the boards and then soldered wires to connect to each pin. The other end of these wires have 8-pin MASCON connectors for plugging into the Classic controller. |

|

| Here is the first of these boards mounted to the console. Though there are three rows of pins, the center is not wired. I discovered that there was not enough room on the small board to handle that many wires! You can already see the space for mounting a second circuit board directly below the first. It will have a third row of pins to replace the unused one on the upper board. |

|

Here is the controller. It is getting pretty crowded with connectors! When it is more complete, I will neaten things up with more cable ties.

I will complete the lower circuit board for the left side connectors and then move on to wiring the corresponding SAMs. In a few weeks, I should have some stop tabs working. |

|

|

Saturday, June 4, 2011 – The public premier and a theater organ that surpasses my Rodgers - finally!

| Last Monday was Memorial Day - the first one in decades that I have not spent in Sacramento performing at the world's biggest jazz festival. The Night Blooming Jazzmen were inexplicably not invited this year! As partial compensation, Karen and I threw a barbecue at our home and invited a couple bands to play. Since the theater organ was just barely playable, I used the occasion to demonstrate it. Because the accompaniment manual had too many sticking or intermittant notes, I used the solo keyboard as the accompaniment. I got an octave and a half of the accompaniment working near the top of the keyboard and I made this the solo for the day. I had to disable the bottom four keys on the great too! I programmed most of the pistons to use Hauptwerk and a few became toggle stop tabs. I played a couple tunes and then turned the console over to Ken Rosen, who had given me the console two years ago. Here you can see him taking the organ for a spin. It took a while for Ken to get used to the top manual being the accompaniment. Also, Ken has a much harder touch than I and this resulted in some interesting bad contact problems! Cory Edelman, another theater organist, was also at the BBQ and played the organ for a while. |

|

| I spent most of the next week in the DC area but I got right back to the organ when I returned Friday night. Here is the instrument early Saturday morning. Karen helped me take it apart so I could readjust the keyboards and get them all working properly. |

|

| I took each keyboard back to my "lab" and carefully adjusted every key so they would turn "on" at the proper point in their travel. I used the cheap Yamaha keyboard as my test tool. I started with that stubborn accompaniment keyboard. To my surprise, it wasn't all that bad. I did a careful adjustment and then returned it to the console. I plugged in its connectors and tried it out. It was perfect. I then did the same with the great manual and reinstalled it in the console too. |

|

| To my surprise, the accompaniment reverted to its intermittent and stuck notes! Clearly there was a mechanical interaction between the two keyboards. With Karen's help, I watched carefully as we swung the great up and down to see how it contacted the accompaniment assembly. As it closed, it put pressure on the accompaniment contact box on the rear of the assembly, causing it to bend slightly. This, in turn, caused the "on" point for the keys to change, making them come on too quickly. Indeed, many were now on all the time. I took the accompaniment back to the lab and studied it carefully. Someone had remounted the contact box on spacers to lift it slightly. I removed these and secured it as firmly as I could to the metal frame that holds it to the key cheeks. I then readjusted all the keys. I reinstalled both keyboards in the console. It was not perfect, but it was much better. With the two in place, I continued to adjust the accompaniment keys until it took pressure from both arms to cause a new failure. I will need to further stiffen the accompaniment - but I also need to figure out how to do this. |

|

| I left the bolster assembly out of the console so I can begin work on wiring over the coming weeks. All the keyboards now work correctly. I can still cause notes on the accompaniment to come on by applying a great deal of pressure to other keys - but this is unlikely in standard playing. In fact, in the last 24 hours, I have not gotten a single failure in normal playing. The theater console now makes a better theater organ than my Rodgers 945, for the first time. All the keyboards and pedals work, plus it has many more pistons and an extra swell shoe. I will continue to play on it looking for any problems. In the meantime, I have some new ideas on how to wire the bolster... |

|

|

Saturday, May 28, 2011 – What a difference a week makes

| It was quite a busy week at work - but I couldn't wait to return home and work on the organ again. There s plenty to do now. I bought another 1,600 feet of 26 gauge wire and 500 cable ties. Karen and I built a jig to hold eight colors of wire for making cables. We need lots of cables! |

|

| I used the long table in my "lab" to stretch the cables, secure the MASCON connectors on each end, and finish off with cable ties. The laptop shows the wiring diagrams for the units I had completed before: the three manuals, sets of toe studs, expression pedals ... The open notebook is the documentation I received from Classic. It shows the expected cable makeup to each set of pins on the Console Controller. |

|

Here is said console controller - getting full of cables. All the cables on the main panel have to exit to the right so that the controller can hinge open for servicing. I wired up each keyboard first. I discovered that the accompaniment keyboard has many stuck and intermittent notes. It is unusable for the moment, so I disconnected its voltage line to keep it from playing until I can take the organ apart and work on it. The Great and Solo keyboards were much better. Each has a few sticky keys - but they basically work.

I used a special feature of the controller that allows one to test the pistons and toe studs without having them try to fire off the SAMs. After verifying that each works and is wired correctly, I moved these cables from the piston section of the controller to the stop section In this way, they will generate MIDI signals I can use to connect to Hauptwerk's own combination action. My stops wont move but I can change registrations a bit.

I wired up the four expression pedals (including the crescendo). The crescendo works for a few minutes and then stopped completely. I discovered that the Klann potentiometer rack I had installed actually cut one of the wires when it moved! I repaired the wire and then cable tied it to a safer place. |

|

| Here you can see most of the wiring for the Accompaniment and Great keyboards. The white cable clamps are actually inexpensive plastic conduit that is used to route lamp wires along walls. It has a strong adhesive along the pack for mounting to surfaces. It is molded to snap open and closed to allow easy access for wires. You can buy this stuff at any home improvement store for about $12 per five foot length. This is enough material to make dozens of small clamps. |

|

| Many cables had to be routed behind the controller box because of the aforementioned fact that the cables had to exit to the right of the box. I passed these over the plywood and into the cavity that used to hold analog oscillators in the original organ. The fall board the holds the key switch and pedal lights folds up to hide this. |

|

| This evening, I programmed Hauptwerk to recognize the top two manuals, all the pistons, the effects toe studs, and the swell pedals. I even programmed the accompaniment pistons as extra toggle-type stop controls for some important (loud) stops like the posthorn, xylophone, and glock. I could then play the organ. Granted - its really now a two-manual organ that has limited stop control - but I can really play it. Click on this photo to watch a movie of me playing a chorus of the old 20s tune "Turkish Towel". |

|

|

Sunday, May 22, 2011 – The Classic controller and the organ starts to play!

This has been a very busy weekend. I was in Washington DC on Wednesday when the shipment arrived from Classic Organ Works with all the console controller components. I flew back to Los Angeles on Thursday but I went straight to UCLA with my daughter to see a musical. I did not see the box from Classic until almost midnight.

I woke early on Friday and unpacked the box. Here you can see the various units. The tall green box is the console controller itself. The low gray box with electrical outlets is the AC Controller. The Black box to the front eight is actually not from Classic - it is a five-port MIDI interface I purchased last week from MOTU.

The notebook is full of documentation. I'll have to read it soon.

That was all I could do today because ,my daughter, Erica, was graduating from Pepperdine Law School. I had to leave to go to the commencement exercises, followed by various social get-togethers.

I found just enough spare time in the afternoon to place the AC COntrol Unit in the console and wire it up to the key switch and console lights. I can now turn on the switch and see the console light up. |

|

Now it is Saturday and I can finally concentrate on the controller. I skimmed the documentation, paying careful attention to the various block diagrams and cabling descriptions. I set up everything on the table in my "lab" where I could reach things more easily than in the console. Karen helped me move the pedalboard into the lab. Since I installed new Peterson contacts on the pedals, I knew these would work well and make a good test platform.

Here you see how I cabled the pedalboard to the controller. You can also see the cables from the "CRTL-3", a numeric keypad with character display that will be used to control the Classic system. Finally, I build an ersatz stop tab by wiring a small MASCON connector to a handy +12V terminal on the controller. I can use this to turn stops "on" for testing. |

|

I connected the giant 70W Astron power supply to the controller and turned it on. At first, things behaved strangely. I wrote an email message to Classic with questions - but I also studied things much more carefully and discovered that several cables were attached backwards. I had taken a description in the documentation too literally, I suppose. In ay case, I traced the wires back from their connectors on the interior of the controller and found the error. With the cables now in properly, I turned on the system again.

Here you see the CRTL-3 unit responding properly. |

|

| I set up my laptop and ran MIDI monitoring software and a simple software synthesizer. Within a minute or so, I had the pedals playing! I then switched over to Hauptwerk and programmed two theater organ ranks to connect properly to the pedalboard and to the ersatz stop tabs. I could now select stops (using the MASCON connector) and play the pedals with my hands. |

|

That was quite enough for Saturday. I woke Sunday and began mounting the Classic components in the organ console. I chose to place the Controller on the low-note side of the console so that I could still swing it open to access the interior for servicing. There is plenty of room to reach all the pins. I mounted the AC Control Unit underneath so that the power cord can exit the console easily. I mounted the MIDI interface and Classic MIDI terminal box ion the high-note side to allow easy access to a computer set up to the right of the organist. The Astron power supply is directly underneath.

I replaced the pedalboard and hooked everything together. |

|

Erica, our new Juris Doctor, testing the organ for me. She turned on the key switch and played the pedals.

It is a but less than two years since I started this project. Now I can see a clear path to getting the organ fully functional. It will now take a lot of wiring and testing. |

|

|

Sunday, May 1, 2011 – A Needed Switch

The control box from Classic will be coming with their AC Control Unit (ACCU). This is a box that manages all the AC power in the console. It allows a single on-off switch to control all the various individual power devices - including the SAM power supply, the console lights, the console controller (gray box), and amplifies. I have a problem: I do not have an on-off switch on the console! This should have been easy to remedy - just purchase one and install it. However, this was not actually trivial. All reasonable electrical switches are made to mount on either circuit boards or panels that are less than 1/4" thick. Every part of my console is made of wood at least 3/4" thick!

The solution is to bore out the reverse side of the wood to make a small area thin enough to accept a switch. With this in mind, I set off to purchase a key switch. I looked on line and found a a local electronics supply house with a good selection. I stopped by after work and discovered all the switches they had allowed the key to be removed only in the switch's "on" position! This would not work for me and I wonder why this is the norm. I purchased an SPDT switch that allowed the key to be removed in both positions. It had the longest threaded shank too - 3/4".

I had wanted to mount the switch on the bolster - but the thought of boring against the curved surface worried me. If I damaged the bolster I would have a hard time replacing it. I went to "plan B" and decided to mount the switch on the fall board. Here you can see how I created the bore on the reverse side of the board. |

|

| With the switch in place, I remounted the fall board on the console. This required Karen's assistance. Here you see Karen dusting a bit before we close up the fall board once again. |

|

| Here is the on-off switch in its new home. It is an easy reach for the organist. Now when all the equipment arrives from Classic in a week or so, I will be able to switch it on! |

|

|

Wednesday, April 14, 2011 – A Visit from Henry Wemekamp

It has been a while since I have worked on the theater organ project. I have come to a point where I really need to wire up the console to its controller for the next steps. My plan has always been to use a controller from Classic Organ Works. They have a product that is a perfect match for projects like this in their catalog. Referred to by their engineers as the "gray box", this assembly takes inputs from all the keys, stops, and pistons on the console and provides the combination action and MIDI translation required to interface to an external computer for tone generation - including drivers for a huge number of SAMs. Before I started this project, I contacted Classic and ended up talking with Henry Wemekamp, the owner and president. Henry's idea was to use this theater organ project as a test case for next generation controller they were about to start developing. Unfortunately, various factors, including the economic recession, have delayed the work on the new system longer than any of us would have predicted back then.

Henry and his wife Norma were on vacation this week in the Los Angeles area and they visited Karen and I last night. Here is a photo of the two of us at the console. We had a great time sharing stories with one another about how we ended up working with organs - and also discussing the pros and cons of various types of digital cameras. We also agreed on a near-term course of action for the project. Classic will ship a current model of the controller so that I can move on with the project. Since the new model will be built in the same physical chassis and have the same pin connections to the organ controls, I will be able to switch easily to the new model when it is available.

By the way, Classic is now advertising for a software engineer who will be a key person on the controller design effort. If any reader is interested in this, please visit Classic's Job Openings site. |

|

|

Thursday, August 19, 2010 – Lights!